Super Retina Resolution

Our scanners have the industry's best resolution of 0.029 mm/pix and an accuracy of 0.010 mm, which makes the scanned object look exactly like the original. We call this Super Retina resolution because the scan result reveals details that are invisible to the naked eye. Our jewelry scanner is the best solution for scanning jewelry, shadow bands, and gemstones.

Today, the jewelry world has evolved. Customers seek unique personalized pieces precisely tailored to unconventional stones, shapes and sizes. What was once a significant challenge, even for experienced jewelers, has become effortless thanks to cutting edge technology. Introducing Microform three d, a next generation three d jewelry scanner perfect for capturing the tiniest details of fine jewelry and precious gems. If your goal is to create precise digital replicas that preserve every intricate detail, our scanner offers retina resolution and accuracy of zero point zero two nine millimeters per pixel so the result appears just as if you were viewing the model with your own eyes. Microform three d stands out with a unique rotating platform positioned opposite the camera, allowing you to scan precious gems in just three minutes from a single setup. You no longer need extra time to align separate scans of the stones top and bottom. Exceptional accuracy extends across an expansive two hundred by one hundred millimeters work area, eight times larger than Thunk three d scanners and twice as large as Elux three d. A movable six megapixel camera achieves an overall scanning resolution of twenty two megapixels across the entire area. This generous scanning area comfortably accommodates larger items such as watches, buckles, and bracelets. Notice how precisely our scanner captures every detail on this ninety by sixty millimeters buckle. Another key benefit is the removable scanning table enabling you to scan even larger objects without work space constraints, statues, antique weapons, and other large scale items, while preserving exceptional detail and precision. At the heart of Microform three d is our proprietary analog projector, delivering deep, detailed, and cost effective scans. We use premium optics and detailed and cost effective scans. We use premium optics and high quality materials to ensure reliability, durability and consistent performance. The Microform software is user friendly and built specifically for jewelers. Our experts provide prompt, professional online support twelve hours a day, seven days a week, along with comprehensive training to get you up and running quickly. With over seven years on the market and numerous positive client reviews, you can trust our equipment's quality and service. We provide a fourteen day money back guarantee, allowing you to verify the quality with confidence. Microform three d is available in three versions. Beginner, ideal for smaller workshops with basic requirements and budgets. Pro, for experienced jewelers who regularly use scanners featuring two times the scanning speed and enhanced retina resolution workspace, extended online support and a two year warranty. And, Enterprise for larger studios with a four year warranty, rapid equipment replacement and unlimited complimentary staff training. Because we avoid expensive trade show exhibitions, we offer more competitive pricing that directly benefits you. Special terms and attractive discounts are available for small businesses. Learn more on our website. Purchasing Microform three d supports Ukraine's fight for freedom. Our scanners are developed and manufactured in Ukraine with warehouses in the US and Poland ensuring fast worldwide delivery. Visit our website for your complimentary consultation today.

Download Brochure (4.7 MB)

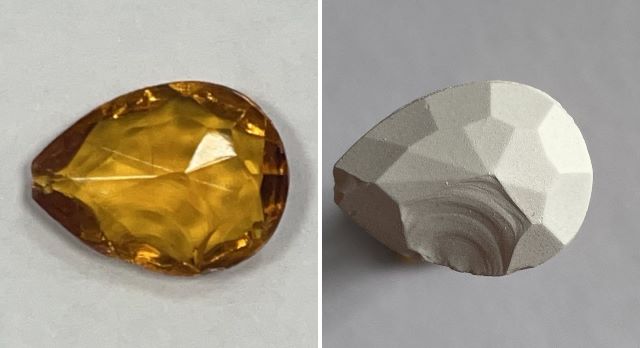

Hi, I'm Heather. I would like to review our Microform three d Scatter with you today. I have thirty years experience in the jewelry industry and five years with CAD design. And I have to say the CAD design has been a game changer in our industry. However, it was missing some points and it ended up being now that we needed to buy a scanner and I did a ton of research and I needed a micro scanner to scan all the delicate little bits that jewelry has. The three categories where we use our scanner the most, and I tell you it has been a game changer, is when you have a model or a design that's your inspiration piece, and you're wanting to replicate that piece, but it may have unique lines to it, you can scan your item into our Microform three d scanner, and you can actually import it and then create your new design right around the scanned piece. So as you can see here, here's my new design, but I scanned it right off of my sample ring. This was the sample scanned piece that I brought in from our Microform scanner, And I was able to replicate the piece or again, having my inspiration piece guide me along the way. It offers a lot more support than importing the pictures. A lot of times that's what we'll do as CAD designers is import four pictures and how to cross section them and try to, with your millimeter gauge, try to figure it all out. Well, when you actually have an imported model in your software, you use that as your range markers, and it really does speed up the process. So duplicating an image or an inspiration piece is one very, very key factor that we do. Number two, are those unique stones. So as you can see here, I have a very uniquely cut citrine stone. We've scanned it already into our Microform scanner. And I wanted to show you here how simply it imports in to the scanner. And we can bring it right into our software. Sorry. So I've scanned it already here. I've imported the unique gem. I've applied a material to it. And just to show you as reference, you can see every facet when you're now creating maybe a basket, a setting, a ring, you can do whatever you want with it now because all these unique shapes are actually inside the software and I don't need to rely on my millimeter gauge anymore to create the gem. Last but not least is our matching bands. We do a ton of matching bands for our clientele here. And so I did the same thing. The client had a band on one side of their ring, they wanted us to make a band for the other side. So I just simply scanned in their first ring. And then I was able to model the second ring right over top of my scanned image. And I have just perfection here. It was very easy for my Goldsmiths to finish with very little modifications. I give two thumbs up. The support is wonderful. If I ever need to get ahold of Microform three d support team, they always get back to me right away. I haven't had a problem. The machine is simply it's small, it's not over overpowered or oversized. The software is super easy to use. I can use it, anybody can use it, that's the truth. But again, I just can't say enough about it. We love it. So I highly recommend the Microform three d scanner for your jewelry needs.

See reviews from our customers

How Jewelry 3D Scanners Can Benefit You:

Jewelry Creation and Reproduction

- Matching Wedding Bands: Precisely craft identical wedding bands by scanning complex surfaces—ideal for replicating intricate details that are hard to measure manually.

- Heirloom Replication: Create new jewelry pieces based on existing ones without disassembling the originals, preserving sentimental value.

- Gemstone Scanning: Capture the unique shapes and sizes of gemstones to ensure a perfect fit in mountings and bezels.

- Art Preservation: Preserve digital copies of valuable or fragile artworks, reproducing sculptures and decorative elements without risking damage.

Download Scan Examples for Jewelry

Design, Repair, and Prototyping

- Intricate Repairs: Perform complex jewelry repairs by scanning pieces and designing perfect-fitting components.

- Rapid Prototyping: Quickly prototype small parts for industrial design, testing forms and fits before mass production.

- Scaling and Modifying: Scan and scale objects to different sizes, saving significant modeling time.

Miniatures and Collectibles

- Miniature Scanning: Digitally reproduce miniature figurines for collectibles or tabletop games, creating 3D models for printing or virtual reality.

- Coins and Medals: Document and analyze numismatic collections, determining authenticity and assessing item conditions.

Download Scan Examples for Miniatures

Mechanical Components (CAD)

- Watch Parts: Analyze and reproduce small mechanical components of watches, aiding in repair and restoration.

- Mechanical Parts Scanning: Reverse-engineer parts for reproduction or modification, ensuring quality control and precision manufacturing.

- Keys and Locks: Reproduce complex key structures and analyze the security of locking mechanisms.

Download Scan Examples for Mechanical Components (CAD)

Scanning process

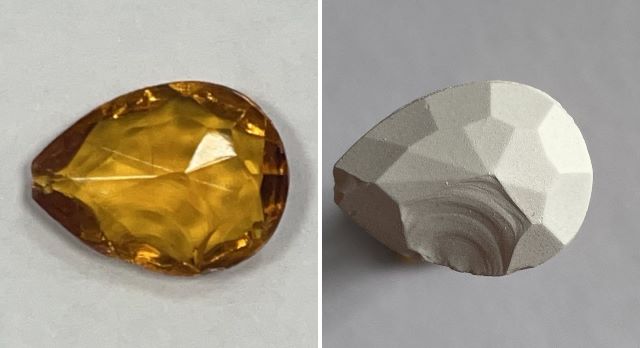

To scan a model, you need to mount it securely to avoid any movement during scanning.

Models also need to be coated with a special spray that makes them white. Two types of spray are available at present. The first is chalk-based and coats models in small particles of chalk. More modern sprays are specially formulated to dissolve in air over time.

Engineered specifically for high-precision scanning of small gemstones. Unlike other SLS scanners, its camera is oriented horizontally. This allows:

- Scanning gemstones from a single setup, capturing both the top and bottom sides simultaneously.

- Preventing the stones from falling during scanning, unlike other scanners.

Conventional diamond scanners can only scan convex objects. The MicroForm3D captures every dimple and defect.

The MicroForm3D includes special stands for scanning gemstones simultaneously from two sides. The scanner tilts the table first to one side and then to the other.

The scanning process yields a 3D model that you can use to create jewelry in a CAD program. You can also showcase your models on your website.

The images above are of a 17-mm gemstone.

Download Scan Examples for Jewelry

3D-scanning miniatures

The MicroForm3D jewelry 3D scanner is also suitable for scanning miniatures. In fact, it is the best tool for copying a miniature. Only our scanner can provide a faithful reproduction that includes even the smallest details. Other scanners are simply unable to do this or cost ten times more. Look at the scan below. You can see all the defects and even marks from the mold.

Download Scan Examples for Miniatures

High-Quality Equipment

We employ industrial-grade cameras and high-quality lenses, enabling us to deliver superior results. Combined with cutting-edge software based on unique algorithms, you'll receive quality that exceeds the cost of our 3D scanner, the MicroForm3D. This device is specifically designed to scan objects with retinal resolution, ensuring the finest detail is captured with precision.

Get More Info & Reserve Yours

Comparison with Competitors

We are not afraid of competition, so we have combined the features of jewelry scanners currently on the market into a comparative table for your convenience.

| Company/Model |

Work Area (mm) |

Resolution (mm/pix)¹ |

Camera |

Price² |

| Thunk 3D |

80x60 |

0.062 |

1.3MP Mono |

$4,900 |

| SuperbMelt |

100x80 |

0.039 |

5MP Mono |

$4,850 |

| BlueCast Easy Lab |

150x110 |

0.058 |

5MP Mono |

$6,799 |

| eLUXE3D |

125x75 |

0.032 |

8MP Mono |

$9,950 |

| MicroForm3D |

200x100 |

0.029 |

6MP Mono |

$3,999–9,999 |

| Artec Micro II |

200×150 |

0.047 |

13MP Color |

$19,999 |

All mentioned trademarks belong to their respective owners.

1. The formula used for calculation was – Working area width (mm) / Camera resolution (pix).

2. The price is obtained from open sources and may differ from the current one, please clarify with the seller.

Save Up to 30%

Get More Info & Reserve Yours

Select Your MicroForm3D Scanner Model

Discover the perfect 3D scanner package tailored to your needs. Whether you're a beginner exploring 3D scanning or an enterprise seeking advanced capabilities, we offer options to suit every requirement and budget. Compare our packages below to find the one that's right for you.

|

Beginner |

Pro |

Enterprise |

| Price | $4,999 | $7,000 | $9,999 |

| Work Area (mm) | 125x85 | 200x100 | 200x100 |

| Resolution (mm/pix)¹ | 0.035 | 0.029 | 0.029 |

| Scan Speed | 1x | 2× | 2× |

| Part Fixtures | 4 | 7 | 9 |

| Warranty | 1 year | 2 years | 4 years |

| Support | Email only | WhatsApp, Email, more | WhatsApp, Email, more |

| Support Speed | Up to 2 days | Quick 12h/7d support | Quick 12h/7d support |

| Training Provided | Manual Only | 2h Live Session | Unlimited Training |

| Fast Replacement | No | No | Yes |

| Scan-to-CAD Courses | No | No | Yes |

Save Up to 30%

Get More Info & Reserve Yours

Minimum System Requirements

- 64-bit Windows 8/10/11

- 16 GB RAM

- NVIDIA card with 2 GB RAM

- Fast SSD (recommended)

- 4GB of HDD free space

- USB 3.x Type-C

Software

We developed software specifically for the MicroForm3D with lots of unique features. The software is currently available for Windows 8/10/11. Once the scanning is done, you'll get an STL file that you can open in any program that supports STL files, such as ZBRUSH, RhinoGold, MatrixGold, Jewelery cad dream and more.

Unlimited support

For your convenience, we have introduced unlimited online support. Ask us as many questions as necessary until you learn how to use the scanner confidently. We provide online training and quick support via WhatsApp. You will be assisted by one of the engineers who designed the scanner, so the information you get will be highly reliable. One hour is usually enough for us to explain how the scanner works. We are always happy to help you and admire your great results.

See reviews from our customers